The Ultimate Guide to Cable Stranding Machines: Types, Benefits, and Applications

In today’s fast-paced manufacturing world, cable stranding machines stand as a cornerstone in producing reliable and efficient cables. Whether it’s for powering cities, enabling seamless communication, or supporting advanced industrial systems, the role of these machines cannot be overstated.

Cable stranding is twisting multiple wires or conductors together to form a single, unified structure. This not only enhances the mechanical strength of the cable but also improves its conductivity and flexibility. Over the years, technological advancements have revolutionized stranding processes, making them more precise, efficient, and adaptable to various applications.

This article delves deep into the world of cable stranding machines, exploring their types, benefits, and applications across different industries. Whether you’re an industry professional seeking insights or a curious reader aiming to understand the technology, this guide aims to equip you with all the essential information.

Let’s unravel the intricacies of cable stranding machines and discover how they are shaping the future of cable production.

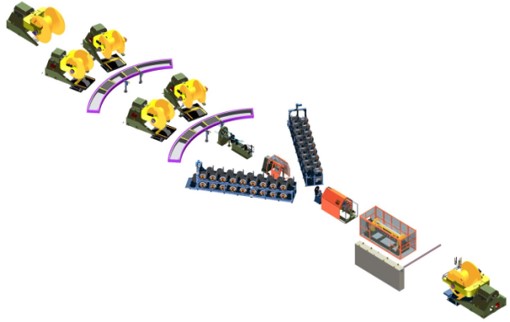

Central Cable Stranding Machines and Armouring Line

What Are Cable Stranding Machines?

Cable stranding machines are essential tools in the production of electrical and communication cables. Their primary function is to twist or strand individual wires or conductors together to form a single, unified structure. This process enhances the cable’s mechanical strength, flexibility, and electrical conductivity, making it suitable for a wide range of applications.

The Role of Cable Stranding Machines

Cable stranding machines play a critical role in ensuring the durability and performance of cables. By tightly winding conductors in a specific pattern, they reduce internal stresses and improve the cable’s ability to withstand mechanical strain. This is especially important in industries such as energy, telecommunications, and construction, where cables must perform reliably under various conditions.

How Cable Stranding Works

The stranding process involves arranging multiple individual wires around a central core. Depending on the desired application, these wires can be twisted in several configurations:

- Concentric Stranding: Wires are helically wound in layers around a central core, creating a balanced and symmetrical structure.

- Bunched Stranding: Wires are twisted randomly, which is ideal for smaller cables.

- Sectoral Stranding: The wires are shaped into segments for compact designs, often used in power cables.

Why Stranding Matters

Stranding is crucial because it:

- Enhances Flexibility: Stranded cables are more flexible compared to solid-core cables, making them easier to install and use in dynamic environments.

- Improves Conductivity: The tight arrangement of conductors minimizes electrical resistance, ensuring efficient current flow.

- Increases Durability: Stranded cables are less prone to damage from bending, vibration, or external forces.

A Key Element in Cable Manufacturing

Modern cable stranding machines come equipped with advanced features such as automated controls, high-speed operation, and precision stranding mechanisms. These innovations not only improve production efficiency but also ensure consistent quality, meeting the high standards demanded by various industries.

Cable stranding machines are more than just equipment—they are the backbone of reliable and high-performing cable production. Their contribution to electrical and communication networks underscores their importance in today’s interconnected world.

Types of Cable Stranding Machines

Cable stranding machines are indispensable in the production of electrical and communication cables, ensuring durability, flexibility, and enhanced conductivity. Depending on the application and material type, different types of cable stranding machines are used in the industry. Below, we explore the primary types of these machines, highlighting their features, advantages, and applications.

1. Rigid Stranding Machines

Rigid stranding machines are widely used for high-speed production of power cables and large cross-sectional conductors. They operate without back-twist, making them ideal for creating compact and symmetrical cable designs.

Key Features:

- High production efficiency and reliability.

- Suitable for aluminum and copper conductors.

- Robust design for heavy-duty applications.

Applications:

- Medium and high-voltage power cables.

- Large cross-section conductors for industrial use.

2. Planetary Stranding Machines

Planetary stranding machines are designed for sensitive materials such as optical fibers and aluminum-clad steel wires. These machines reduce internal stress by rotating the bobbins during the stranding process.

Key Features:

- Precise tension control.

- Capability to handle delicate and torsion-sensitive materials.

- Flexibility in strand configurations.

Applications:

- Telecommunications cables.

- Specialized data and signal transmission cables.

3. Tubular Stranding Machines

Tubular stranding machines feature a rotating tube that houses the bobbins, enabling high-speed production. They are commonly used for smaller cable constructions with multiple strands.

Key Features:

- Exceptional speed and efficiency.

- Uniform stranding for enhanced durability.

- Minimal setup time for different cable configurations.

Applications:

- Low-voltage power cables.

- Multi-core cables for household and commercial use.

4. Bow Stranding Machines

Bow stranding machines are compact and versatile, ideal for producing medium and small-sized cables. They are known for their simplicity and cost-efficiency.

Key Features:

- Compact and lightweight design.

- Low maintenance requirements.

- Energy-efficient operation.

Applications:

- Control cables and signal wires.

- Braided and twisted pair cables.

5. Concentric Stranding Machines

Concentric stranding machines create cables with concentric layers of wires around a central core. This type of stranding ensures excellent mechanical strength and electrical conductivity.

Key Features:

- Uniform layering with minimal distortion.

- Enhanced mechanical properties.

- Compatibility with various wire gauges.

Applications:

- Electrical power distribution cables.

- High-performance industrial cables.

6. Drum Twisting Machines

Drum twisting machines are specifically designed for manufacturing large and complex cables, such as submarine and high-voltage power cables.

Key Features:

- Capable of handling large diameters and heavy weights.

- Smooth operation with advanced tension control.

- Ideal for long-length cable production.

Applications:

- Subsea cables for offshore projects.

- High-voltage transmission cables.

Choosing the Right Machine

Selecting the appropriate cable stranding machine depends on various factors, including the material type, cable size, production volume, and specific industry requirements. Each type of machine is tailored to meet distinct production needs, ensuring efficiency, reliability, and quality.

By understanding the unique features and capabilities of these machines, manufacturers can optimize their production processes and deliver superior cable products.

This section is a detailed exploration of cable stranding machine types, providing practical insights for both industry professionals and enthusiasts. For more comprehensive guidance, consulting manufacturers and technical experts is highly recommended.

wire and cable machinery

Key Benefits of Cable Stranding Machines

Cable stranding machines are an indispensable part of modern cable manufacturing processes. Their advanced designs and technology bring numerous advantages to the production of electrical and communication cables. Here are the key benefits that make these machines essential in the industry:

1. Enhanced Flexibility and Durability

Cable stranding machines enable the production of highly flexible cables without compromising their structural integrity. By intertwining individual wires in specific patterns, these machines ensure that the cables can withstand mechanical stress, bending, and external impacts. This is particularly crucial for applications in industrial, automotive, and marine environments, where cables are exposed to constant movement and harsh conditions.

2. Improved Electrical Conductivity

The stranding process optimizes the distribution of electrical current across the cable. By arranging conductors in a precise and consistent manner, cable stranding machines reduce resistance and energy losses. This results in more efficient power transmission, making these cables suitable for high-performance electrical systems.

3. Customization for Diverse Applications

Modern cable stranding machines are equipped with adjustable settings, allowing manufacturers to produce cables tailored to specific requirements. Whether it’s for low-voltage power cables, high-frequency data cables, or specialized industrial cables, these machines provide the flexibility to meet diverse customer needs.

4. High Production Efficiency

Cable stranding machines are designed to operate at high speeds, significantly increasing production rates. This efficiency is critical for large-scale manufacturing operations, where time and cost savings are essential. Advanced models with automation features further enhance productivity by reducing manual intervention.

5. Consistency and Precision

One of the standout benefits of cable stranding machines is their ability to maintain consistent quality across batches. The automated processes ensure that each cable meets precise specifications, minimizing the risk of defects and ensuring compliance with industry standards.

6. Cost-Effectiveness

Although the initial investment in cable stranding machinery can be significant, the long-term cost benefits are substantial. The high-speed production capabilities, minimal material wastage, and reduced labor costs contribute to an overall decrease in manufacturing expenses.

7. Compatibility with Advanced Materials

As the industry shifts towards innovative materials like optical fibers, aluminum-clad steel, and eco-friendly conductors, cable stranding machines have evolved to handle these materials effectively. This compatibility ensures that manufacturers can stay ahead of market demands.

8. Enhanced Safety Features

Many modern stranding machines come equipped with safety mechanisms that protect both operators and equipment. These features include automated shut-offs, overload protections, and ergonomic designs, creating a safer work environment.

In conclusion, cable stranding machines are at the heart of efficient, high-quality, and versatile cable manufacturing. Their ability to enhance cable performance, reduce costs, and adapt to new materials makes them an essential investment for manufacturers aiming to stay competitive in a fast-evolving industry.

Applications of Cable Stranding Machines

Cable stranding machines play a critical role in the production of a wide variety of cables used across industries. These machines not only enhance the structural integrity of cables but also optimize their electrical and mechanical properties. Below are some of the most common applications of cable stranding machines:

1. Electrical Power Cables

Cable stranding machines are extensively used in the production of electrical power cables, which require precise engineering to handle high voltage and current. Stranding improves the flexibility and durability of power cables, making them suitable for various applications, such as:

- Transmission Lines: High-voltage cables for long-distance power transmission.

- Distribution Networks: Cables for medium and low-voltage power supply in residential, commercial, and industrial settings.

- Underground and Submarine Cables: Robust cables for challenging environments, including underwater and subterranean installations.

2. Telecommunications and Data Transmission Cables

The demand for high-speed and reliable communication has surged, driving the need for advanced cable manufacturing. Stranding machines are crucial in the production of:

- Fiber Optic Cables: Planetary stranding machines are ideal for these delicate cables, minimizing internal stress.

- LAN and Ethernet Cables: Machines ensure precise stranding for enhanced data transfer efficiency.

- Coaxial Cables: Stranding improves shielding and reduces signal interference, essential for telecommunications.

3. Automotive and Aerospace Cables

The automotive and aerospace industries rely on specialized cables to ensure safety and performance. Stranding machines produce cables with superior flexibility and heat resistance, meeting the strict standards of these sectors. Applications include:

- Automotive Wiring Harnesses: Lightweight yet durable cables for modern vehicles.

- Aerospace Communication Cables: High-performance cables designed to withstand extreme conditions.

4. Industrial and Heavy-Duty Cables

Industrial environments demand cables that can handle mechanical stress, chemical exposure, and extreme temperatures. Stranding machines are vital for producing:

- Control Cables: Used in machinery for signal transmission and control.

- Mining and Oil Exploration Cables: Heavy-duty cables capable of withstanding harsh conditions.

- Crane and Elevator Cables: High-tensile strength cables for vertical and heavy lifting operations.

5. Marine and Offshore Applications

Marine and offshore cables face unique challenges, such as exposure to saltwater, pressure, and mechanical wear. Stranding machines ensure these cables are robust and reliable for:

- Submarine Communication Cables: Long-distance undersea cables connecting continents.

- Offshore Wind Farms: Power cables for transmitting energy from turbines to the grid.

- Marine Navigation Systems: Reliable cables for critical navigation and communication systems.

6. Renewable Energy Projects

Renewable energy systems, such as solar and wind power, require specialized cables to transmit energy efficiently. Stranding machines produce cables for:

- Solar Panel Arrays: Flexible cables connecting panels to inverters and grids.

- Wind Turbine Networks: High-performance cables that can endure dynamic mechanical stress.

7. Custom and Specialized Cables

In many cases, industries require bespoke cables tailored to unique applications. Stranding machines allow for high customization in:

- Robotics and Automation: Highly flexible cables for moving parts and robotic arms.

- Medical Equipment: Cables with exceptional precision for sensitive devices like imaging machines.

- Defense and Security Systems: Specialized cables for high-reliability communication and control.

Final Thoughts

The versatility of cable stranding machines enables them to meet the demands of various industries, from telecommunications to renewable energy. Their ability to produce cables with enhanced durability, flexibility, and performance ensures their essential role in modern infrastructure and technology. Investing in advanced stranding technology not only improves cable quality but also enhances overall productivity and efficiency.

Would you like further details or additional sections? 😊

drum twister hattı assembling and armouring line

Latest Innovations in Cable Stranding Technology

The field of cable stranding technology has witnessed remarkable advancements in recent years, driven by the demand for more efficient, sustainable, and high-performing cable manufacturing processes. These innovations have not only streamlined production but also significantly enhanced the quality and durability of cables. Below, we explore the latest trends shaping the future of cable stranding machines.

1. Automation and AI Integration

Modern cable stranding machines are increasingly incorporating automation and Artificial Intelligence (AI) technologies. These advancements enable:

- Enhanced Precision: Automated systems ensure consistent stranding with minimal human intervention, reducing errors and improving cable quality.

- Real-Time Monitoring: AI-driven sensors and software provide live data on machine performance, allowing for proactive maintenance and minimizing downtime.

- Optimized Production: Smart algorithms adjust parameters like speed and tension to achieve optimal stranding efficiency based on cable specifications.

2. Eco-Friendly Production Methods

Sustainability is becoming a core focus in cable manufacturing. Innovations in cable stranding technology now prioritize:

- Energy Efficiency: Machines are being designed to consume less energy while maintaining high productivity levels.

- Reduced Waste: Advanced stranding techniques minimize material waste during production, lowering the environmental impact.

- Recyclable Materials: Manufacturers are exploring the use of eco-friendly and recyclable materials in machine components and cable insulation.

3. Improved Energy Efficiency

Energy efficiency remains a critical area of development. The latest machines feature:

- High-Efficiency Motors: These reduce energy consumption without compromising performance.

- Adaptive Power Modes: Machines now adjust energy usage based on production demands, optimizing energy expenditure during peak and idle times.

4. Integration of Smart Controls

Smart controls have revolutionized how operators interact with cable stranding machines. Features include:

- Intuitive Interfaces: Touchscreen controls and user-friendly dashboards simplify machine operation and configuration.

- Remote Accessibility: Operators can monitor and control machines remotely via mobile apps or cloud-based platforms, enabling flexible production management.

- Predictive Maintenance Tools: Smart controls analyze machine performance trends and predict potential failures, reducing costly repairs and downtime.

5. Modular Machine Designs

The shift toward modular designs has provided manufacturers with more versatility and cost-efficiency. Key benefits include:

- Customizable Configurations: Machines can be tailored to specific production needs by adding or removing modules.

- Simplified Upgrades: Modular designs make it easier to upgrade existing machines with new technologies.

- Reduced Footprint: Compact, modular systems save valuable floor space in production facilities.

6. Enhanced Safety Features

Worker safety has also improved significantly with new technological advancements:

- Automatic Shutdown Mechanisms: Machines are equipped with sensors that halt operations in case of malfunctions or safety risks.

- Barrier Systems: Physical and virtual barriers prevent operator access to hazardous areas during operation.

- Training Simulators: Virtual reality (VR) simulators help operators learn machine handling without risks, ensuring safer workflows.

7. Advanced Materials and Cable Designs

Innovations in the materials used for cables and stranding processes include:

- High-Strength Alloys: Stranding machines can now handle advanced materials like high-tensile alloys, ensuring stronger and more durable cables.

- Hybrid Cable Production: Machines are optimized for hybrid cable designs, combining different materials to meet specific application requirements.

The latest innovations in cable stranding technology are redefining the standards for efficiency, sustainability, and quality in cable manufacturing. As automation, energy efficiency, and smart controls continue to evolve, the industry is poised to meet the growing demands of modern applications. Staying abreast of these advancements is crucial for manufacturers aiming to remain competitive in this rapidly advancing field.

drum twister hattı assembling and armouring line

Top Manufacturers and Their Offerings

When it comes to cable stranding machines, the market is enriched with manufacturers providing innovative solutions tailored to various industry needs. Below, we highlight two leading companies in the sector—Frekans Makina and MSS Machinery—and explore their unique contributions.

Frekans Makina

Frekans Makina is a renowned name in the cable manufacturing industry, known for its cutting-edge technology and reliable machinery. Specializing in advanced cable stranding machines, the company offers solutions designed to meet the demands of high-performance and large-scale production.

Key Offerings:

- Rigid Stranding Machines: These machines are engineered for the efficient stranding of copper, aluminum, and steel wires. Their robust design ensures stability even at high operational speeds.

- Planetary Stranding Machines: Ideal for sensitive materials, Frekans Makina’s planetary machines reduce torsional stress, making them perfect for high-precision applications like fiber optic cables.

- Custom Solutions: Frekans Makina collaborates closely with clients to deliver customized stranding solutions that align with specific manufacturing requirements.

Why Choose Frekans Makina?

- Cutting-edge automation features for seamless operation.

- Durable and energy-efficient designs that minimize production costs.

- A global network of support for installation, maintenance, and training.

MSS Machinery

MSS Machinery has established itself as a global leader in wire and cable manufacturing equipment. With a focus on innovation and customer satisfaction, MSS Machinery offers state-of-the-art cable stranding machines that cater to a wide range of industrial applications.

Key Offerings:

- Tubular Stranding Machines: These high-speed machines are designed for superior performance, ensuring uniform stranding with minimal material waste.

- Bow Stranding Machines: MSS Machinery’s bow stranders are optimized for medium-sized cables, delivering consistent results with high efficiency.

- Integrated Solutions: The company provides end-to-end solutions, combining stranding machines with additional equipment like cable taping and sheathing systems.

Why Choose MSS Machinery?

- High-speed production capabilities to meet tight deadlines.

- Modular machine designs that enable easy upgrades and maintenance.

- Strong emphasis on sustainability, with machines built for energy efficiency and reduced environmental impact.

Innovative Edge

Both Frekans Makina and MSS Machinery stand out for their commitment to quality and innovation. Their machines not only enhance operational efficiency but also ensure durability and precision, making them trusted partners for manufacturers worldwide.

By choosing either of these companies, you are investing in top-tier technology that ensures your cable production process is seamless, cost-effective, and future-proof.

drum twister hattı assembling and armouring line

Conclusion

Cable stranding machines are the backbone of modern cable manufacturing, ensuring durability, flexibility, and efficiency across various industries. Whether it’s for power transmission, telecommunications, or specialized applications, choosing the right stranding machine is critical to achieving optimal results.

In recent years, companies like Frekans Makina and MSS Machinery have revolutionized the cable manufacturing industry with their innovative solutions. Frekans Makina, renowned for its cutting-edge technology and customer-centric approach, offers a wide range of machines tailored to meet the diverse needs of the cable production sector. Similarly, MSS Machinery stands out for its precision engineering and commitment to sustainability, providing high-quality equipment that ensures both efficiency and environmental responsibility.

Investing in advanced stranding machines from trusted manufacturers like Frekans Makina and MSS Machinery not only enhances production capabilities but also secures a competitive edge in an ever-evolving market. By staying ahead of technological advancements and industry trends, businesses can achieve unparalleled success and reliability in cable production.

As the demand for robust and efficient cables continues to grow, embracing the expertise and innovation of leaders like Frekans Makina and MSS Machinery will undoubtedly pave the way for a stronger, more connected future.